Feature

1 Excellent anti-slip,flame resistant,anti-aging

2 Abrasive resistance

3 Elegant and easy to install

4 Fit the modern archtecture stair size and color 5

5 With excellent wear-resistance, abrasive resistance, ageing resistance, stain resistance; nontoxic and environmental friendly.

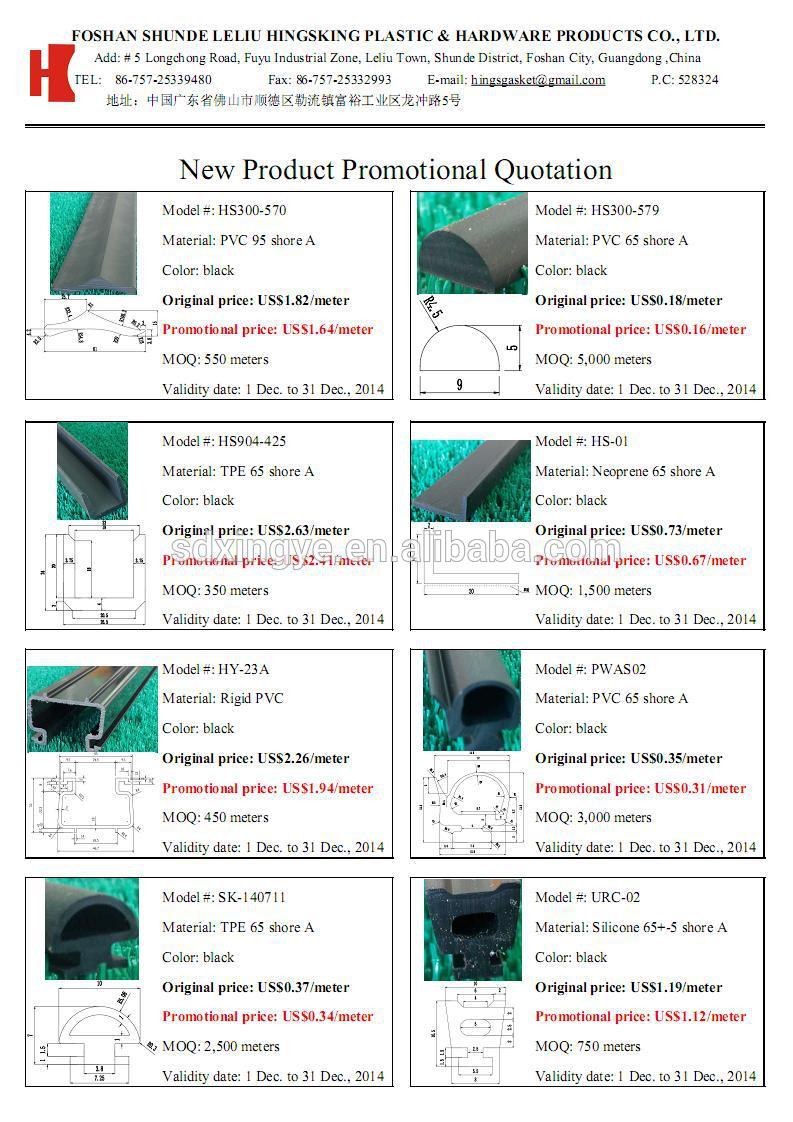

Specification

Product name | aluminum pvc stair nosing |

Material | PVC/Aluminium |

Application temperature | -10~110°C |

Size | width:60mm thickness:3.6mm |

Length | According to requirement |

Shape | According to customer request/drawing |

Color | Black, White,grey or according to customers’ requirements |

Application | Stair Flooring |

Packaging | Carton or according to customers’ requirements |

|

Packaging & Shipping

Package:

1.Bag and strong export carton customer special packing requiring are welcome.

2.Each carton has a certain weight or length

3.The length,N.W,G.W,trademark, color, products' name will display outside the cartons.

Shipping and payment:

1)Usually, all orders are dispatched within 10-15 days upon receipt your order or as your request after making payment.

2).After the goods leave our factory, email you the photograph for loading goods to container, the INVOICE and PACKING LIST, B/L and others as your request.

3) Payment terms is T/T, L/C, Western Union, PayPal

Our Services

Guarantee And After-sale Service:

- 1 years' product warranty period.(Non-human destruction)

- use-friendly environmental rubber raw material

- 24 hours online service by email or telephone

- free sample available.

- free logistic and technical support

- provide promotional price every month

Quality Control:

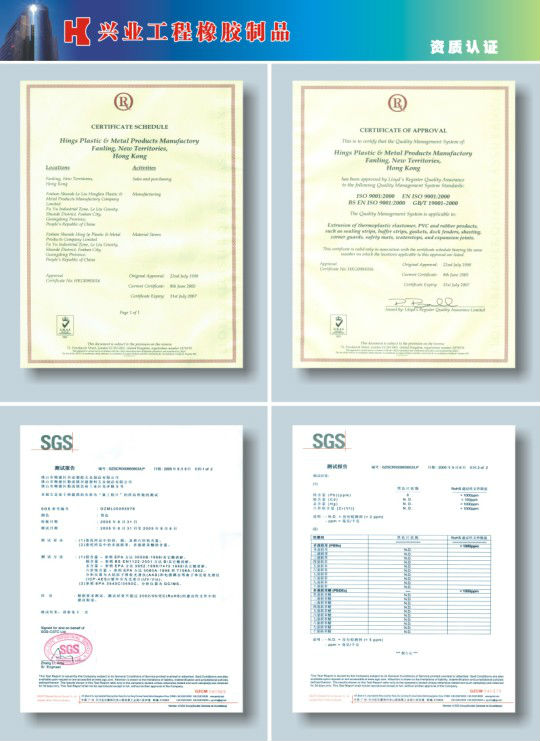

we always pay more attention to the raw material quality, standard quality control system and team are responsible to ensure the product quality in every process with different machine like extrusion equipment and mould pressing equipment.

1).The quality of our products all through the QC staff to check.

2).All of our products get through strictly quality system to control it, after four re-check before shipment, including purchasing materials, production processes, processing and packaging.

3).National Institute of Standards by SGS product certification testing.

Besides stair nosing products, we make lots of different kinds of rubber/plastic products, We have improved our style and technology to meet our various of customers and we will try our best to provide best quality products, best service and best prices!

1. Serive: can supply the OEM service according to the drawing or the sample.

from beginning to ending and after sales. Treat customer as friend

2. Mould production: within-house tooling, reduced the developing cost,

Mould charge can be return when comes to a certain quantity.

3. Accept your required quantity at initial development.

4. High technology in plastic extrusion and injection.

5. Good quality by virgin material and strict quality control.

6. Fast & cheap delivery by getting big discount from long cooperation forwarder.

Rubber Extrusion Capabilities

Hingsking has the following capabilities with extruded rubber:

- Dense & Sponge materials

- Extrusion & Molding

- Custom Compounding (durometer, colors, chemical resistant)

- Dual Durometer

- Splicing, Vulcanizing, Corner Molding

- Adhesive Application

- Custom Protective & Retail Packaging

- Extruded & Calendered Sheet

- Molded Sheetstock

Hingsking has the extensive experience with the following materials:

- EPDM

- Neoprene

- Natural Rubber

- Nitrile

- Silicone

- TPE

- PVC

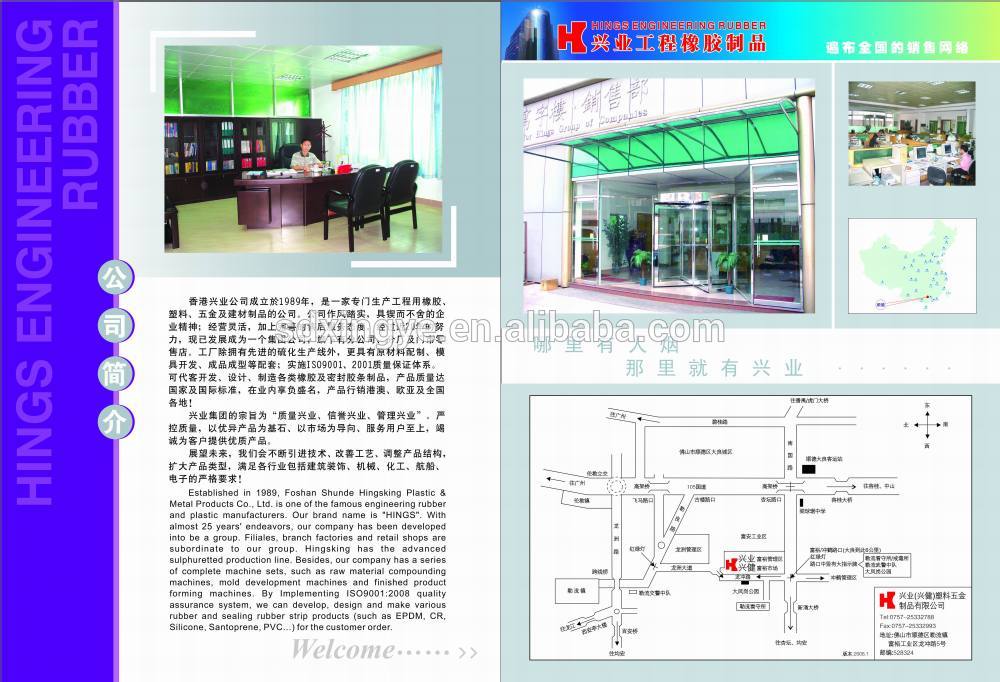

Foshan shunde Hings Plastic & Metal Products Co., Ltd is a leading manufacturer in various rubber sealing kits. Our company has opened 25 years with excellent long history, has advanced production equipment to ensure the quality and price concessions.

Our Certification:

It will be glad to have the opportunity to establish business relationship with you !

our website:

FAQ

HOW TO PLACE YOUR ORDER?

1. Inquiry send requirements to HINGSKING.

2. Received HINGSKING quick and professional quotation.

3. Confirm price, lead time, artwork, payment term etc.

4. HINGSKING sales send Performa Invoice for payment. And confirm it after paid.

5. Initial Production Stage: sales send HINGSKING technical drawing for customer to confirm. Then begin mould production. When mould finished, make samples according to your request, send you photo or sample to approve,

6. Middle Production Stage: After sample approved, then make mass production, send photos to show the production situation, confirm the estimated delivery time.

7. End Production Stage: send production photo or random samples to you, You can also arrange the third party to do inspection.

8. Clients make the payment and HINGSKING ship the goods. Also can accept payment term against copy of B/L. Checking shipping status for clients.

WHAT ARE YOU LOOKING FOR ?

We are the most professional Rubber&Plastic manufacurer!

We are the most favourable customzied expertise moulders!

We are always offering you best quality, satisfied service and competitive pirce!

WHY CHOOSE US?

1. establish in 1984;

2. focus on rubber and plastic products;

3. 100% production and quality control in-house;

4. buyers worldwide benefit from our 25 years export experience;

5. sell to Home Depot;

6. export to worldwide up to 5million.